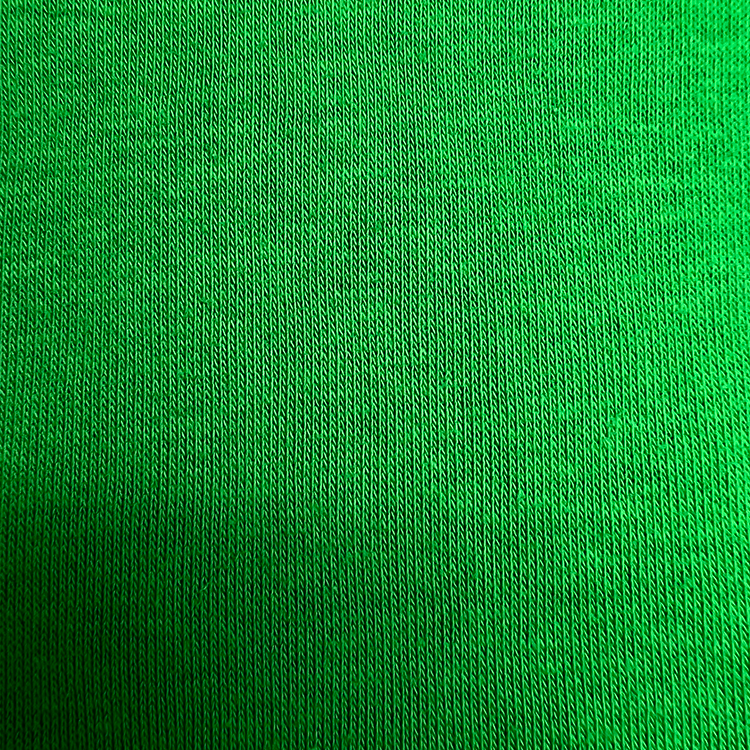

When it comes to sweatshirt fleece fabric, especially stretch fleece used in loungewear and athleisure, one of the most critical—but often misunderstood—factors is the fabric weight, commonly measured in GSM (grams per square meter). While design and color catch the eye, GSM determines how a garment performs, feels, and endures. In the manufacturing world, we often say that choosing the right fabric weight is like laying the right foundation—it affects everything built on top of it, from the garment’s drape to its thermal efficiency and longevity.

Fabric weight is more than just a number. A lower GSM fleece might feel lighter and more breathable, making it ideal for spring or indoor wear, but may lack the substantial feel consumers expect in cold-weather clothing. Higher GSM fabrics, on the other hand, provide excellent warmth and structure, but they need to be engineered with care to maintain comfort and flexibility. That’s where material composition becomes essential. For our stretch sweatshirt fleece, we use high-quality blends that incorporate polyester full stretch yarn, offering a combination of softness, recovery, and performance even in heavier weights.

Many buyers assume that heavier always means better, but the best GSM depends on the use case. For hoodies meant for transitional seasons, a medium-weight fleece around 280–300 GSM may offer the ideal balance of comfort and warmth. For more robust outerwear or oversized winter loungewear, GSM levels above 320 can provide a more substantial and premium hand feel. As experienced manufacturers, we work closely with clients to align GSM selection with target market preferences and functional goals. It’s a decision that influences everything from product pricing to consumer satisfaction.

A common pitfall for newcomers in the garment sector is underestimating how GSM interacts with fiber type and construction. A fleece made with standard yarn might become stiff or lose stretch at higher weights. That’s why we emphasize using polyester full stretch yarn across our fleece lines—it ensures that even dense fabrics remain flexible and wearable. This material is engineered to maintain elasticity over time, which not only enhances comfort but also supports shape retention after repeated washing and wear, a crucial factor for consumer trust in quality.

Consistency in GSM across production batches is another mark of a reliable supplier. We implement stringent controls to ensure each lot of fleece meets the specified weight tolerance. In B2B orders where branding and sizing standards are at stake, such precision reduces variability and enhances production efficiency. Our clients appreciate that whether they order 500 meters or 50,000, the fleece performs exactly as expected—smooth, stretchy, and dimensionally stable. This reliability is a key selling point that strengthens long-term partnerships.

For designers and sourcing managers, understanding GSM and the role of materials like polyester full stretch yarn opens up more strategic decision-making. It empowers them to select the right fabric weight for diverse product lines, from lightweight yoga sets to heavyweight lounge hoodies. The GSM value becomes a tool to balance comfort, cost, and design language—an essential part of product development that directly impacts customer experience and brand positioning in a competitive market.

Ultimately, GSM isn’t just a technical detail; it’s a design driver. It affects not only the look and feel of fleece garments but also their performance, durability, and market success. By combining the right GSM level with advanced materials like polyester full stretch yarn, manufacturers can deliver fleece fabrics that meet the evolving needs of today’s fashion brands. For us, it’s not just about making fabric—it’s about helping you create products that feel as good as they look.

English

English Français

Français